Introduction

Threading a sewing machine may look confusing at first, especially for beginners. One missed guide or incorrect tension can cause broken threads, skipped stitches, or tangled fabric.

In this complete beginner-friendly tutorial, you’ll learn how to thread a sewing machine correctly, step by step, whether you use a mechanical or computerized model. By the end, you’ll be ready to sew smoothly and confidently without frustration

Quick Answer: Raise the presser foot, guide the thread through the tension discs, thread the needle, insert the bobbin, and pull up the bobbin thread to start sewing smoothly.

Prepare Your Sewing Machine Before Threading

Sewing machine Prepare your sewing machine before beginning to thread it. Switch off the machine and lift the presser foot to release discs of tension. Insert your thread spool into the spool pin and it might be needed to have a cap to hold down the thread. Gently pull the thread to avoid tangles to enable it to pass through without difficulties.

Raising the needle up to the utmost position assists in straightening thread guides. These steps of preparation are essential to be threaded and run smoothly. Preparation prevents frustration and mechanical issues

Understand the Key Parts Used in Threading

It is useful to know the sewing machine parts that are used in threading in order to follow the instructions with confidence. These are the spool pin, thread guides, tension discs, take-up lever, needle bar and bobbin case. These guides bring the upper thread to the needle.

The thread bobbin is fed independently in the bobbin where there is a bobbin case underneath the needle plate. The knowledge of these parts will enable you to accessibly thread your machine as well as easily diagnosis any threading challenges. This is basic knowledge that is essential to every user of a sewing machine.

How to Thread the Upper Thread Correctly

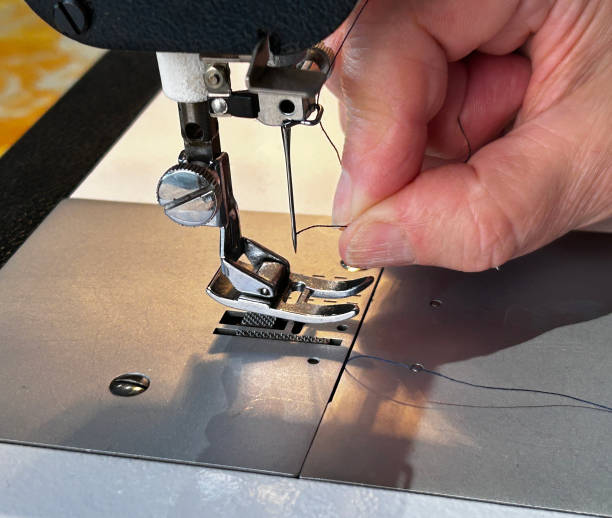

To thread the upper part, draw the thread off the spool and run it through the lower most thread guide on the top. Next, take the threading route and move the thread around tension discs and the take-up lever. Ensure that the thread fits well in each guide to ensure that it is in proper tension.

Lastly, insert the needle in the front back direction or in the direction given by your machine. Proper threading of the upper thread makes the stitching balanced and it does not slip. Take your time with this step in order to gain confidence.

Beginner Tip:

If your thread keeps breaking, always rethread the machine with the presser foot raised. This allows the thread to sit properly inside the tension discs.

This process involves winding and loading in the bobbin

The lower thread is contained in the bobbin which is to be wound and correctly inserted. To spin the bobbin put it on the bobbin winder spindle and pull the thread on the spool, on to the bobbin. Winder- Set the machine running to fill up the bobbin.

When it comes time to wind a bobbin, install your bobbin then as identified in your machine. Ensure that the bobbin thread is moving smooth and also is correctly placed. Correct bobbin winding and insertion are essential in easy sewing and quality of the stitches.

Pulling up the bobbin thread

Once you have threaded the top thread and opened the bobbin you must remove the bobbin thread by pulling it. Take the thread on the upper and then turn the handwheel in the direction towards you. The needle will roll down and grab the bobbin thread, and drag it up through the needle plate.

Pull softly both the threads to the back of the machine, and leave a few inches loose. This process makes the threads prepared to sew and it avoids getting tangled during the commencement of the sewing process. It is simply a minor yet significant step of threading your sewing machine.

Adjust Thread Tension for Balanced Stitches

This has to do with thread tension and quality of stitches. Post threading Tension Checking Thread a set of sample need sewing practice on scrap material. The bobbin and upper threads are to mesh up evenly and never to bulge or have loose loops. Adjustment of tension dial is necessary through your machine manual as a guide.

The correct tension eliminates the possibility of thread rupture and uneven stitches. Making routine observations on tension and in making adjustments on the tension will keep your sewing machine in maximum operation.

Best threading errors to prevent

Errors are common such as leaving out thread guides or threading the needle in wrong position or incorrect insertion of bobbin. The mistakes lead to jamming of threads, missed stitches or broken threads.

Threading should not be hurried and the guide path of the thread in each guide should be checked. Always be sure that the presser foot is high when tension discs are being threaded. Knowing how to spot and avoid these errors is very time-saving and frustration-free and easier and more pleasant to sew.

Threading aids and tools facilitated

Most sewing machines now have aids in threading such as automatic needle threaders that make it easier to thread the needles. These tools would save time and help to avoid eye strain particularly among beginners. Also, in case of necessity, such tools as tweezers or magnifying glasses would be used to thread the needle by hand.

Threading aids improve the precision and confidence during the process of learning how to thread a sewing machine. Use these to take advantage of these features to help in making threading easier and faster.

Threading parts cleaning and maintenance methods

The thread guides, tension discs and the bobbin case should be cleaned regularly to ensure the threading is smooth. Wearing-of thread-lint and dust will also lead to thread jams or tension issues. It is important to clean these parts using a small brush or compressed air.

Application of lubricants To moving parts as suggested in your machine manual. Regular servicing prolongs the life of your sewing machine and guarantees a smooth running of the machine and threading becomes better and more dependable.

Troubleshooting Common Threading Problems

Give your machine a second check the threading path then continue on to jam or add stitches that are not even. Make sure that the thread is properly clamped in tension discs and guides. Adjust the bobbin and thread tension. Insert the needle again, when needed.

Go to your manual to get a particular troubleshooting advice. Troubleshooting Problems can be solved quickly, so as not to interrupt your sewing project. The ability to detect and correct most threading errors is a necessity.

Summary table for how to thread a sewing machine

| Step | Description | Tips for Success |

| Prepare machine | Turn off, raise presser foot, place spool | Avoid tangles, ensure smooth thread flow |

| Thread upper thread | Guide thread through all tension and guides | Follow machine path carefully |

| Wind and insert bobbin | Wind bobbin evenly, insert correctly | Check proper rotation and placement |

| Pull up bobbin thread | Turn handwheel to catch bobbin thread | Pull threads to back gently |

| Adjust tension | Test stitches and adjust dial as needed | Achieve balanced stitches |

| Use threading aids | Utilize automatic threaders and tools | Save time and reduce strain |

Conclusion

Sewing projects depend on knowing how to thread a sewing machine in order to become successful. You can guarantee a hassle free stitching by preparing your machine, threading the upper thread carefully and bobbin, and tension so that you will not have thread breaks or jams. The common mistakes can be avoided and the process will be easier to complete with the help of threading aids, particularly those who are new to the process.

The machine can be maintained in good condition by cleaning it regularly and troubleshooting. This sewing machine tutorial has easy instructions and tips on how to easily and confidently thread your sewing machine. Learning how to thread gives you more pleasure in sewing as well as the opportunity to make exquisite projects.

FAQs

Should I sew using it with my sewing machine on?

To prevent any accidents during threading, it is better to switch off the machine.

What makes me know whether my bobbin is put in the right place?

Your bobbin must rotate according to the direction that is labeled on your manual, and move thread evenly.

Suppose the needle thread continues to break?

Path of threading check, tension, needle condition, rethread cautiously.

Does each sewing machine come with an automatic needle threader?

There is none, although numerous contemporary machines have this option to make threading easier.

What is the frequency of cleaning threading parts of my sewing machine?

Wipe between each few projects or where you can see lint developing or experiencing stitches.